- 艾宝物联IOBOV® ─ 工业无线测控专家

用PLC构成装配流水线控制系统梯形图和语句表

- 2018-09-08

一、目的

用PLC构成装配流水线控制系统

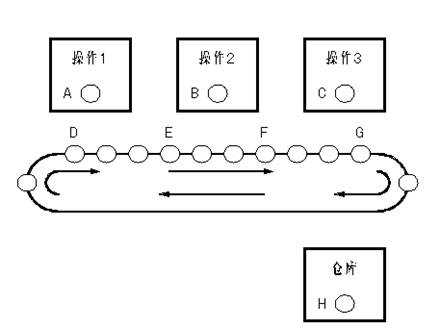

图1 装配流水线控制示意图

二、控制内容

1. 1. 控制要求

起动后,按以下规律显示:D→E→F→G→A→D→E→F→G→B→D→E→F→G→C→D→E→F→G→H→D→E→F→G→A……循环,D、E、F、G分别是用来传送的,A是操作1,B是操作2,C是操作3,H是仓库。

2.I/O分配

输入 输出

起动按钮:I0.0 A:Q0.0 E:Q0.4

复位按钮:I0.1 B:Q0.1 F:Q0.5

移位按钮:I0.2 C:Q0.2 G:Q0.6

D:Q0.3 H:Q0.7

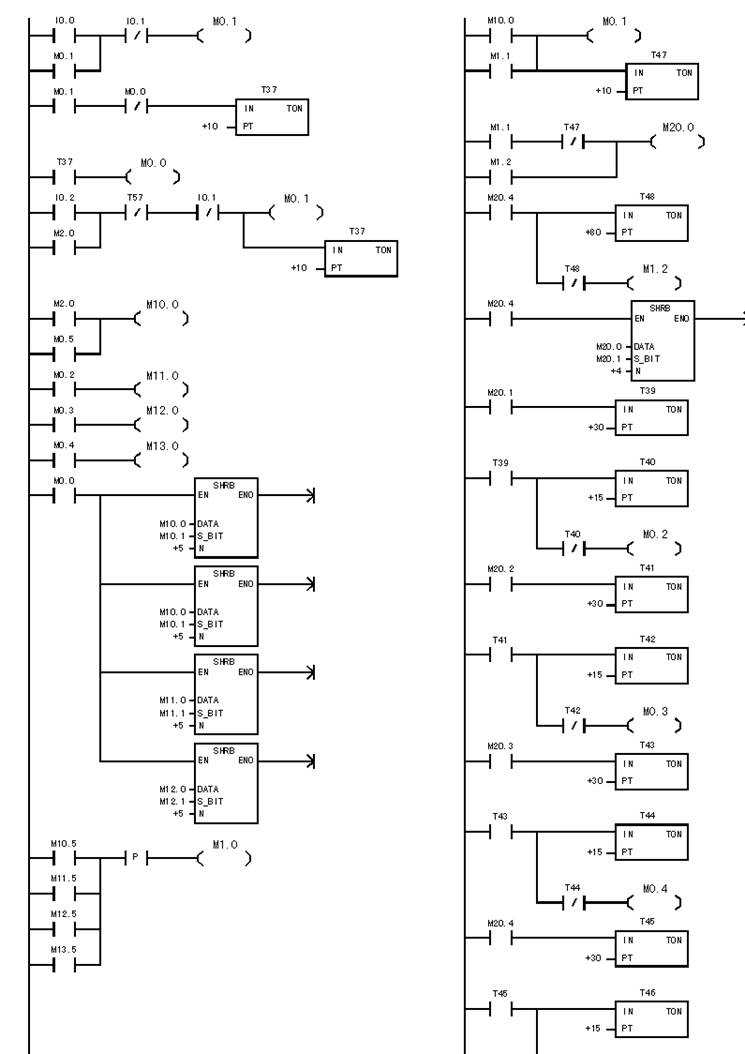

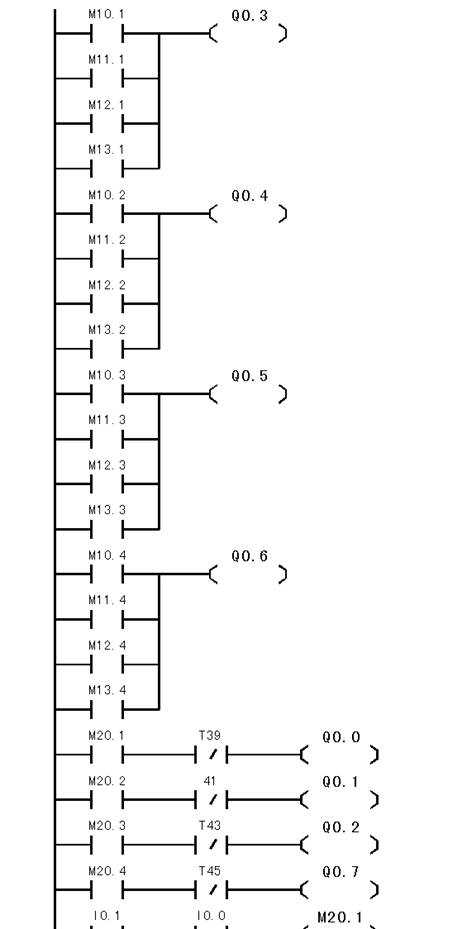

2. 按图所示的梯形图输入程序。

图2 装配流水线梯形图

三、装配流水线控制语句表

|

0 |

LD |

I0.0 |

37 |

= |

M1.1 |

77 |

= |

Q0.3 |

|

1 |

O |

M0.0 |

38 |

TON |

T47,+50 |

78 |

LD |

M10.2 |

|

2 |

AN |

I0.1 |

39 |

LD |

M1.1 |

79 |

O |

M11.2 |

|

3 |

= |

M0.1 |

40 |

AN |

T47 |

80 |

O |

M12.2 |

|

4 |

LD |

M0.1 |

41 |

O |

M1.2 |

81 |

O |

M13.2 |

|

5 |

AN |

M0.0 |

42 |

= |

M20.0 |

82 |

= |

Q0.4 |

|

6 |

TON |

T37,+10 |

43 |

LD |

M20.4 |

83 |

LD |

M10.3 |

|

7 |

LD |

T37 |

44 |

TON |

T48,+80 |

84 |

O |

M11.3 |

|

8 |

= |

M0.0 |

45 |

AN |

T48 |

85 |

O |

M12.3 |

|

9 |

LD |

I0.2 |

46 |

= |

M1.2 |

86 |

O |

M13.3 |

|

10 |

O |

M2.0 |

47 |

LD |

M1.0 |

87 |

= |

Q0.5 |

|

11 |

AN |

T57 |

48 |

SHRB |

M20.0,M20.1,+4 |

88 |

LD |

M10.4 |

|

12 |

AN |

I0.1 |

89 |

O |

M11.4 |

|||

|

13 |

= |

M2.0 |

49 |

LD |

M20.1 |

90 |

O |

M12.4 |

|

14 |

TON |

T57,+10 |

50 |

TON |

T39,+30 |

91 |

O |

M13.4 |

|

15 |

LD |

M2.0 |

51 |

LD |

T39 |

92 |

= |

Q0.6 |

|

16 |

O |

M0.5 |

52 |

TON |

T40,+15 |

93 |

LD |

M20.1 |

|

17 |

= |

M10.0 |

53 |

AN |

T40 |

94 |

AN |

T39 |

|

18 |

LD |

M0.2 |

54 |

= |

M0.2 |

95 |

= |

Q0.0 |

|

19 |

= |

M11.0 |

55 |

LD |

M20.2 |

96 |

LD |

M20.2 |

|

20 |

LD |

M0.3 |

56 |

TON |

T41,+30 |

97 |

AN |

T41 |

|

21 |

= |

M12.0 |

57 |

LD |

T41 |

98 |

= |

Q0.1 |

|

22 |

LD |

M0.4 |

58 |

TON |

T42,+15 |

99 |

LD |

M20.3 |

|

23 |

= |

M13.0 |

59 |

AN |

T42 |

100 |

AN |

T43 |

|

24 |

LD |

M0.0 |

60 |

= |

M0.3 |

101 |

= |

Q0.2 |

|

25 |

SHRB |

M10.0,M10.1,+5 |

61 |

LD |

M20.3 |

102 |

LD |

M20.4 |

|

62 |

TON |

T43,+30 |

103 |

AN |

T45 |

|||

|

26 |

SHRB |

M11.0,M11.1,+5 |

63 |

LD |

T43 |

104 |

= |

Q0.7 |

|

64 |

TON |

T44,+15 |

105 |

LD |

I0.1 |

|||

|

27 |

SHRB |

M12.0,M12.1,+5 |

65 |

AN |

T44 |

106 |

AN |

I0.0 |

|

66 |

= |

M0.4 |

107 |

R |

M20.1,4 |

|||

|

28 |

SHRB |

M13.0,M13.1,+5 |

67 |

LD |

M20.4 |

108 |

R |

M10.1,28 |

|

68 |

TON |

T45,+30 |

109 |

R |

M1.1,1 |

|||

|

29 |

LD |

M10.5 |

69 |

LD |

T45 |

|

|

|

|

30 |

O |

M11.5 |

70 |

TON |

T46,+15 |

|

|

|

|

31 |

O |

M12.5 |

71 |

AN |

T46 |

|

|

|

|

32 |

O |

M13.5 |

72 |

= |

M0.5 |

|

|

|

|

33 |

EU |

|

73 |

LD |

M10.1 |

|

|

|

|

34 |

= |

M1.0 |

74 |

O |

M11.1 |

|

|

|

|

35 |

LD |

M10.0 |

75 |

O |

M12.1 |

|

|

|

|

36 |

O |

M1.1 |

76 |

O |

M13.1 |

|

|

|